R&D Project ideas

#1. Create and manufacture the Li-ion batteries electrodes based on Si to replace the graphite electrodes:

- specific capacitance of Si-based electrode is 30% higher in comparison with that of the graphite electrode;

- Si-based electrodes are produced in the solvent-free processes making less negative environmental impact.

#2. Apply the high-speed ion-plasma etching in place of liquid chemical etching in order to increase the coefficient of light absorption in silicon plates of solar cells:

- single process, no preliminary or subsequent processing;

- heavy recycling process exclusion (without water consumption and aggravating recirculation process);

- dramatically lower environmental impact of processing.

Instruments

- plasma arc and helicon sources of plasma flows were developed and patented by us. The sources operate in a specific magnetic medium and are used to prepare the substrate and deposit one- or multi-layer thin (0.1+ um) films. The helicon source operates in the modes of deposition and аnisotropic etching.

- consumables are conventional powder or metallurgical alloys and plasma-forming and reactive gases (Ar, N2, O2, H2, SiH4, SF6, etc.)

- the films are deposited by the plasma flow from the consumable cathode of the plasma arc source in РVD processes, and in the plasma flow from the helicon sourcе in PE CVD processes.

- anisotropic etching of silicon is carried out by an accelerated ion-plasma flow from a helicon source

in the mode of ion-plasma etching (IPE).

- the low production cost is due to the high efficiency of plasma sources: in order to obtain 100 cm2*10um film in laboratory equipment, it takes up to 5 minutes*5 kW power.

Team

- Viktor Grebeniuk is the CEO & CFO.

- Valerii Semeniuk, Phys.D. is the CTO & Science Leader of the team, specialist in the field of plasma physics and plasma technologies, develops and improves plasma-technological equipment.

He knows well the possibilities of plasma equipment and continues to open its new opportunities. - Valerii Virko, Phys.D., is the Adviser in plasma physics, the specialist in measurement of plasma specifications.

- Georgii Veremeichenko, Ph.D., is the Patent Expert & Adviser, the specialist in the field of microelectronics and plasma technologies.

- Natalia Globa, Ph.D., is the Principle Specialist in electrochemistry.

- Volodymyr Khomenko, Ph.D., is the Advisor in electrochemistry

- Vyacheslav Chetveryk is the Marketing & PR Manager.

Achievements

1. Silicon based electrode

- technology is attractive for mass production, because it uses the environmentally friendly processing with high deposition rates;

- necessary electronic conductivity of the Si-based electrode is obtained;

- various current collectors and mediate layers were tested;

- manufactured samples are cycled for 300 ... 500 cycles in half-cells within the 40% utilization of silicon in the 40 … 50% DoD mode;

- manufactured samples are cycled for 100 ... 150 cycles in complete cells with 20 ... 40% depletion.

2. Silicon wafer etching

- coefficient of light reflection in the visible wavelength range for standard plates of solar cell elements from mono and polycrystalline silicon is reduced by 5 ... 10% at an anisotropic etching rate of polycrystalline silicon to 5 um/min.

What are we planning to work on

Silicon-based electrode

- adaptation of liquid electrolyte;

- active layer further improvement (e-, i+ conductivity)

- optimization of all deposition processes;

- increase utilized electrical capacity of silicon composite active layer;

- optimization of compatibility of the active layer, current collector and electrolytes;

- testing protocols and BMS variations;

- pouch cell-level

Ion-plasma etching of a silicon wafer

- optimization of the helicon source specifications in the ion-plasma etching mode;

- optimization of the composition of operating plasma-forming and reactive gases mixture.

How we will implement this

- use a multi-chamber equipment and carry out technological processes in the specialized chambers;

- use more precise, fully automatic devices and control tools to minimize human factor and show pre-production scalable prototype;

- vacuum deposition of solid-state electrolyte;

- study more different samples to obtain statistically reliable results;

- test samples in other laboratories under the same / different conditions;

- use best-available materials (substrates, powders, gases etc.) from top-suppliers

- attract additional staff to carry out more of our own research;

- involve advisors from various institutions

What do we need

- equipment and components to build multi-chamber unit and conveyor-simulation;

- own testing equipment and supplies, increase the team of employees, funds to cover the costs of other institutions participating in the tests if necessary;

- expansion of the research network for obtaining statistically reliable results and information exchange at conferences, seminars, etc.;

- cooperation with institutions working on similar projects, where PVD tools are used;

- patenting support;

- commercialization partner in long perspective

Risks for a silicon-based electrode

- we might never be able to get the expected results;

- probably we are moving in the wrong direction or move too slow;

- non-reproducibility of the best sample of the experimental series in the industrial process;

- we might suppose the wrong time we need or wrong TRL we have;

- someone can achieve earlier the same result or better;

- the specific unit price can be higher compared to market-present ones.

What if we get where we want

- we put to the market same or better in many terms Li-ion battery but in addition it will be produced with much less impact on environment;

- we replace polluting etching fabrications with solar-energy powered production zones;

- we still have an instrument free to be used in different deposition application like DLC, decorative, sub-layer formation which can be a subject of another R&D projects

Competitors

- General Motors Corp., USA: it is known only one R&D project using PVD process to make the silicon electrode;

- Enevate Corp., USA: commercialized Si-dominant electrodes

Valuation

- SCORECARD method estimates the Gresem Innovation valuation around $10M (based on Enevate Corp. example launched 2006, $10M in 2011, $30M in 2015) (https://www.crunchbase.com/organization/enevate#/entity)

Funding

- Angel, pre-seed - $1M (closed)

- Investment request of $3M for 20% stake:

a) $3M direct R&D project investments

b) month run expenses are near $15k must increase to $30-40k;

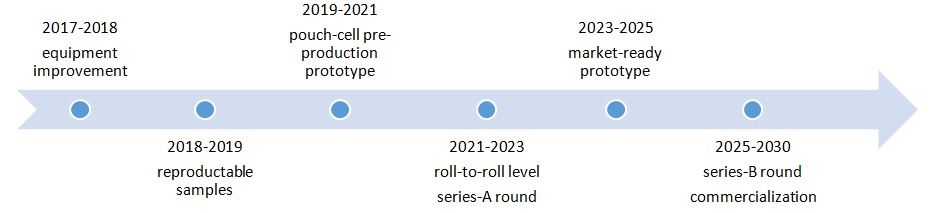

Roadmap for LIB Silicon anode

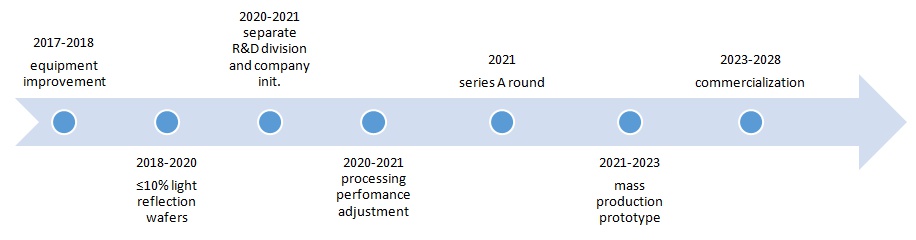

Roadmap for Silicon wafer plasma etching

Exit strategy

- Silicon-based electrode - commercialization on behalf Tier-1 LIB producer with 100% technology transfer (ATL, BYD, Panasonic/Sanyo, LG, Samsung, Tesla, Nissan, GM etc. ). Approximate company valuation $50-100M

- Silicon wafer plasma etching – due to simple implementation technology licensing is preferred but 100% transfer is possible (TOP20 solar-cell/silicon wafer producers, China and US). Approximate company (if separate division initiated earlier) valuation $20-50M